Cosmatos Group, being agents and forwarders of many important steel traders, has gained a lot of experience in the transportation of steel coils. Here you can find information about the transport and specific particularities of the cargo.

Transport Hazards of the cargo

The cargo bears a shifting hazard in case of inappropriate stowage and lashing which, if faulty, may result to causing a dangerous inclination of the ship.

Ship’s safety requirements

Vessel should hold a certificate on cargo ship safety in accordance with the convention SOLAS-74, chapter I, regulation 12. The preparation of a ship for safe loading should include checking of cargo spaces, access to sounding pipes and fire-prevention system and other equipment. The cargo spaces should be cleaned of previous cargo remains, i.e., cleaning / sweeping of the cargo holds. Ship equipment at cargo spaces (e.g., pipelines etc.) should be protected with metal or wooden casings.

Safety requirements for safe stowage

Cargo on board should be placed in consideration of:

- distribution of cargo weight should meet the requirements of vessel’s information on stability.

- the capability to avoid shifting despite of roll motion and vibration.

- the number of rows of stacked coils in cargo holds should be determined in conformity with the admissible specific load of the hold expressed in tons/M2.

- when stowing heavy coils weighing 15 mts or more per piece, a single tier stowage is recommended.

Bottom tier of coils should start first in the wings, working inwards from the sides of the hold towards the center.

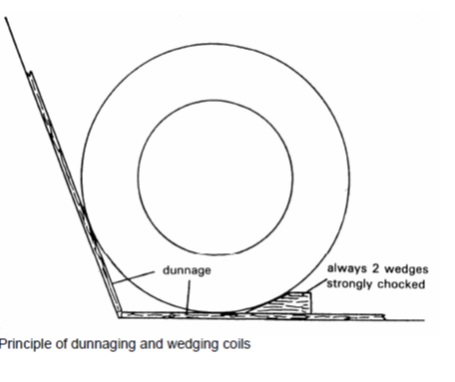

Photo: https://marinegyaan.com/ Wedges should be placed beneath each coil in succession.

Photo: https://puc.overheid.nl/ Fitting at least one locking coil into the stow is vital, as neglecting to do so can cause instability (photo c).

Photo: https://www.tis-gdv.de/ Coils should be stowed across the ship with their axis (eye) fore and aft. Wedges placed at either side of a coil will prevent them from shifting during the voyage at sea. Secure coils to each other with steel banding in varying forms. Pneumatically tightened steel bands that bind the coils, and especially the key one to those stowed immediately below, is preferred.

Photo: https://standard-club.com/ In order to avoid damage to the ship’s structure and to enable an even weight distribution, dunnage must be carefully applied between the ship and cargo, and between cargo tiers. Lay dunnage over strong points.

Photo: https://standard-club.com/

Ship’s officers should ensure that dunnage is laid properly to create frictional resistance and spread the load. Always use sufficient quantity and dimensions of dunnage to avoid exceeding the tank top acceptable loading point.

Preloading steel surveys are usually undertaken by surveyors appointed by the P&I club. The surveyor has a number of duties, the most important of which is to examine cargo damages and to advise the ship’s Master on suitable clauses to be endorsed on the transport documents, especially on bills of lading.